Quick Overview

Flexible Arm. Total Arm Length: 863.6mm 34 inches. Illumination Type: SMD LED. Light Adjustable. Input Voltage: AC 110-240V 50/60Hz. Optical Lens Diopter: 6 Diopter (2.5X). Lens Size: Dia. 127mm (5 in. ). ESD Safe.

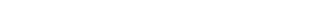

MG16303622 6D Adjustable LED Clamp Magnifying Lamp (ESD)

Power Supply

| Output Power | 12W |

| Input Voltage | AC 110-240V 50/60Hz |

| Power Cord Connector Type | USA 2 Pins |

| Power Cable Length | 1.6m |

| Material | Heavy Duty Plastic |

| Color | Black |

Magnifying Lamps

| System Field of View | Dia. 5 in. |

| System Working Distance | 100mm (3.937 in. ) |

| Stand Type | Flexible Arm |

| Stand Height | 863.6mm 34 inches |

| Horizontal Arm Length | 431.8mm 17 inches |

| Total Arm Length | 863.6mm 34 inches |

| Mounting Hole on the End of Horizontal Arm | Dia. 12.2mm |

| Base Type | Metal Clamp |

| Clamp Opening Size | 0-60mm, 2.36 inches |

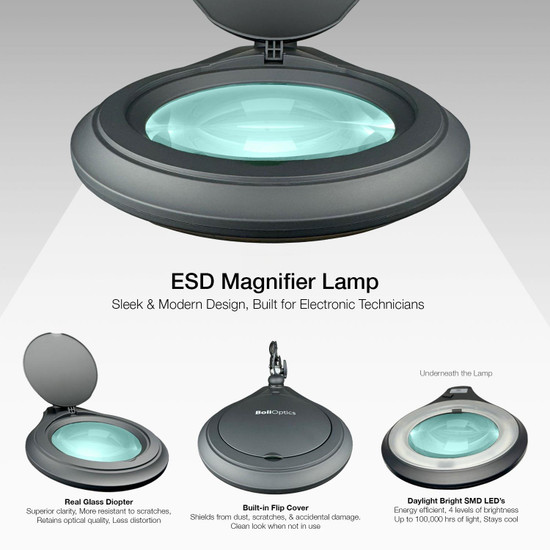

| Illumination Type | SMD LED |

| LED Quantity | 60 |

| Power Supply Adjustable | Light Adjustable |

| Light Source Luminous Flux | 1200 LM |

| Bulb Color Temperature | 5600K-6000K |

| Bulb Color (Wavelength) | White Light |

| Optical Lens Diopter | 6 Diopter (2.5X) |

| Lens Size | Dia. 127mm (5 in. ) |

| Lens Type | Convex |

| Magnifier Lens Material | Green Float Glass |

| Head Size | Dia. 190mm (7.480 in. ) |

| Head Material | Heavy Duty Plastic |

| Head Appearance | Round |

| With Lens Shield | Yes |

| %Bigger Than Object | 150% |

| Swing Arm Material | Heavy Duty Metal |

| Clamp Material | Heavy Duty Metal |

| Work Hours | Up To 50,000 Hours |

Other Parameters

| Surface Treatment | Spray Paint |

| ESD Safe | ESD Safe |

| Color | Black |

| Net Weight | 4.90kg (10.802bs) |

| Dimensions | 820x253x190mm (32.283x9.960x7.480 in. ) |

Technical Info

Instructions

System Field of ViewClose Λ

| Field of View, is also called FOV. The field of view, or FOV, refers to the size of the object plane (i.e., the plane of the point of the observed object perpendicular to the optical axis), or of its conjugate plane (i.e., object to primary image distance), represented by a line value. System field of view is the size of the actual diameter of the image of the terminal display device of the instrument, such as the size of the image in the eyepiece or in the display. Field of view number refers to the diameter of the field diaphragm of the objective lens, or the diameter of the image plane formed by the field diaphragm. Field of view number of objective lens = field of view number of eyepiece / (objective magnification / mechanical tube length) Large field of view makes it easy to observe the full view and more range of the observed object, but the field of view (FOV) is inversely proportional to the magnification and inversely proportional to the resolution, that is, the larger the field of view, the smaller the magnification, and also the lower the resolution of the object to be observed. There are usually two ways to increase the field of view, one is to replace with an objective lens of a smaller multiple, or to replace with an eyepiece of a smaller multiple. |

System Working DistanceClose Λ

| Working distance, also referred to as WD, is usually the vertical distance from the foremost surface end of the objective lens of the microscope to the surface of the observed object. When the working distance or WD is large, the space between the objective lens and the object to be observed is also large, which can facilitate operation and the use of corresponding lighting conditions. In general, system working distance is the working distance of the objective lens. When some other equipment, such as a light source etc., is used below the objective lens, the working distance (i.e., space) will become smaller. Working distance or WD is related to the design of the working distance of the objective lens. Generally speaking, the bigger the magnification of the objective lens, the smaller the working distance. Conversely, the smaller the magnification of the objective lens, the greater the working distance. When it is necessary to change the working distance requirement, it can be realized by changing the magnification of the objective lens. |

Light AdjustableClose Λ

| The brightness of the light source adjustable is very important in the imaging of the microscope. Since the difference of the numerical aperture of the objective lens of high magnification and low magnification is very big, more incident light is needed to achieve a much better resolution when using a high magnification objective lens. Therefore, when observing through a high magnification objective lens, the brightness required is high; when observing through a low magnification objective lens, the brightness required is low. When observing different objects, or feature points of the same object at different positions, the brightness needs are also different; including the difference of background light or reflection within the field of view of observation, it has a great influence on the effect of observing the object, and therefore one needs to adjust the brightness of the light source according to each object to be observed. In the light source capable of providing continuous spectrum, such as a halogen lamp, the brightness adjustment of the light not only adjusts the brightness and intensity of the light, but also changes the spectrum emitted by the light source. When the light source is dark, there are many components of red light, and when the brightness is high, there are more blue spectrum. If the required light is strong and the spectrum needs to be changed, the light can be kept at a brighter intensity, which is solved by adjusting the spectrum by adding a color filter. Take note of the dimming button on the light source, after the On/Off switch is turned on, normally clockwise is to brighten, and counterclockwise is to darken. If it is adjusted to the lowest brightness, the light source should normally be lit. If the naked eye still can't see the object being illuminated brightly, you need to adjust the brightness knob to a much bigger position. Generally, there is scale marking on the dimming knob, which is an imaginary number representing the percentage of brightness, or an electronic digital display, giving the brightness of the light source under the same conditions a marking. |

ESD SafeClose Λ

| Static electricity is a charge that is at static or non-flowing state, and static electricity is formed when charges accumulate on an object or surface. Static electricity can cause malfunction or mis-opeartion of electronic equipment, resulting in electromagnetic interference. In the electronics industry, static electricity can break down integrated circuits and precision electronic components, causing components to age, and can also absorb dust, causing contamination of integrated circuits and semiconductor components, and reducing production yield. In the plastics industry, static electricity can cause film or membrane not wining up uniformly, film and CD plastic discs contaminated with dust, thereby affecting quality. In industrial production, especially in electronic production and processing and inflammable and explosive production sites, electrostatic protection should be taken seriously. ESD means "electro-static discharge." For the methods of ESD treatment with respect to microscope and components, electrical conductivity of the metal should be utilized on the one hand, and on the other hand, electrostatic materials, electrostatic coating and other methods of treatment should be adopted to solve the electrostatic problem. Electrostatic coating is to apply coat that can prevent static electricity. It has electrostatic discharge, dust-proof, mildew-proof, wear-resistant, acid and alkali resistance and other characteristics. The surface of the coating does not generate static electricity or the static electricity is discharged to the safe place through the conductor row. On some components, electrostatic materials may be applied, such as the microscope knob handle, insulation mat, septum, microscope cover etc. |

PackagingClose Λ

| After unpacking, carefully inspect the various random accessories and parts in the package to avoid omissions. In order to save space and ensure safety of components, some components will be placed outside the inner packaging box, so be careful of their inspection. For special packaging, it is generally after opening the box, all packaging boxes, protective foam, plastic bags should be kept for a period of time. If there is a problem during the return period, you can return or exchange the original. After the return period (usually 10-30 days, according to the manufacturer’s Instruction of Terms of Service), these packaging boxes may be disposed of if there is no problem. |

| Packing | |

| Packaging Type | Carton Packaging |

| Packaging Material | Cardboard Box |

| Packaging Dimensions(1) | 54.5x29.5x11.5cm (21.457x11.614x4.528″) |

| Ancillary Packaging Materials | Styrofoam |

| Gross Weight | 3.55kg (7.83lbs) |

| Minimum Packaging Quantity | 1pc |

| Transportation Carton | Carton Packaging |

| Transportation Carton Material | Cardboard Box |

| Transportation Carton Dimensions(1) | 54.5x29.5x11.5cm (21.457x11.614x4.528″) |

| Total Gross Weight of Transportation(kilogram) | 3.55 |

| Total Gross Weight of Transportation(pound) | 7.83 |

| Quantity of One Transportation Carton | 1pc |